1. The main raw materials of soft porcelain technology products: ordinary urban construction waste soil (including loess, red soil, clay, black soil), cement waste block, porcelain and stone powder can be the main raw materials of MCM series products. 2. After more than 30 processes, the soil has good plasticity. The scientific community named this magical new material MCM, which combines the flexibility of organic materials and the aging resistance of inorganic materials, is non-toxic and radiation-free. 3. MCM in photochemical isomerism and controlled curve temperature, can be arbitrary modeling, you can imagine, can be realized. MCM special mechanical system, molding process, to achieve zero emission, zero pollution. Energy consumption and consumables are more than 80% lower than the same kind of products. 4. MCM series products can be recycled and regenerated, or soil essence can be reduced by physicochemical and mechanical treatment, returning to farming.

Soft porcelain also known as soft stone, flexible stone, flexible ceramic tile and so on

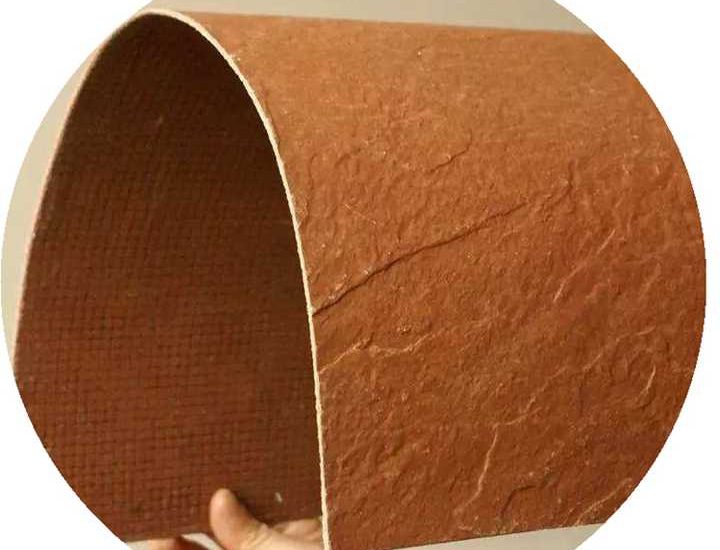

Soft porcelain is not real porcelain or ceramic tile. It is a new type of building material. It is a kind of flexible building facing material, which is made of modified clay (MCM) as the main raw material, using special temperature control modeling, baking and irradiation crosslinking. At the beginning of its birth, it has the appearance effect of ceramic tiles, commonly known as soft porcelain. Later, with the development of technology, it can be developed into imitation of stone, imitation of leather grain and imitation of wood grain. Whatever can be imagined, soft porcelain can be realized

1. Class B1 fire protection, effectively reducing fire risk. 2. It is soft, special-shaped, convenient for construction and strong expressive force. It is made of various natural stone wood, ceramic brick and face brick in the original ecological form. 3. It is light and thin, saving more than 80% of transportation energy consumption, and the thickness is only about 3mm, which greatly saves the cost while ensuring the quality. 4. Anti freeze-thaw, no cracking and pulverization for 50 years. After 100 times of freeze-thaw cycle test, no cracks and falling off.