Prefabricated box house is a kind of light steel system integrated house with standardized design, factory production, modular combination, removable, reusable, easy inventory reorganization, safety and environmental protection, beautiful and efficient. The top, bottom and four walls are packed separately, and the secondary circulation does not need to be disassembled. The ceiling, floor and other materials are moved together with boxes and materials, and the fool type assembly saves a lot of labor costs and material waste. It can be easily and quickly assembled and disassembled, realizing the general standardization of the building. Series development, integrated production, supporting supply, can be stocked and can be used for many times to maximize the cost control.

Characteristics of integrated housing 1. Packing box forming machine equipment adopts Xiamen Liming brand cold bending molding equipment which is the best brand in China. The cutting error of the equipment can reach no more than ± 0.5mm, which is the highest standard in China. The bottom is supported by 50 * 100 square tubes, and the top is made of C-shaped steel 2. Using the whole electrostatic spraying treatment, the service life is longer than that of spray painting. If the spraying time is a little longer, a large area of paint will fall off, and the plastic spraying life is long and the aesthetic degree is high, which can extend the service life of the whole box body. What’s more, we use matte plastic powder with better service life and adhesion. Sunlight does not reflect light. It has higher grade and longer service life. All connection points are treated before electrostatic spraying, which has longer service life and higher aesthetics. No longer worry about long-time paint peeling off or rust on the connection points; 3. The waterproof effect of butyl tape is perfect; the waterproof effect of butyl tape is perfect; the waterproof effect of skin interface is improved by adopting weather resistant adhesive; 4. It can match 50 wallboard, 75 wallboard and 100 wallboard, which is convenient and quick to install; 5. The 831 ceiling tile for ceiling, produced by Weichang, is the designated ceiling material of China Construction iron and Steel Co., Ltd., and the whole box body is higher. 6. The Zhengtai brand power distribution is adopted in the power distribution, and all the electric power distribution systems have ground wires, which are made of national standard lines. Industrial sockets are used to ensure the safety of our electricity use 7. The 160 channel steel type of luxury packing box contains electrostatic spraying, and the built-in stair step is paved with plastic floor, and the fluorescent anti-skid strip is set at the edge of each step, including stainless steel stair handrail. (there are also economical built-in stairs) 8. The production of 160 channel steel style including electrostatic spraying stairs, step and walkway board are made of 3.5mm galvanized sheet. Both sides of the stair steps are made of 160mm channel steel according to the national standard of abdominal competition. The 160C section steel of high-end mass production includes electrostatic spraying stairs, and the steps and walkways are made of 20 mm galvanized sheet. Both sides of the stair step are made of C-shaped steel with the abdominal width of 160mm. (affordable) 9. The walkway canopy of luxury packing box is made of 3.5mm galvanized checkered plate. Our corridor plate is galvanized plate, which is the only one in China at present. The canopy support of the corridor is made of galvanized 8mm column bottom plate and 6mm common support plate for two boxes (there are also economical type walkway plate with thickness of 20mm). Canopy plate double sided 0.4, 12kq foam composite board 299 meters canopy plate (with edge).

| Name | material | specification |

| Main frame | galvanized steel sheet | Thickness: 2.3 / 2.5 / 2.7 / 3.0 / 3.5 / 4.0mm |

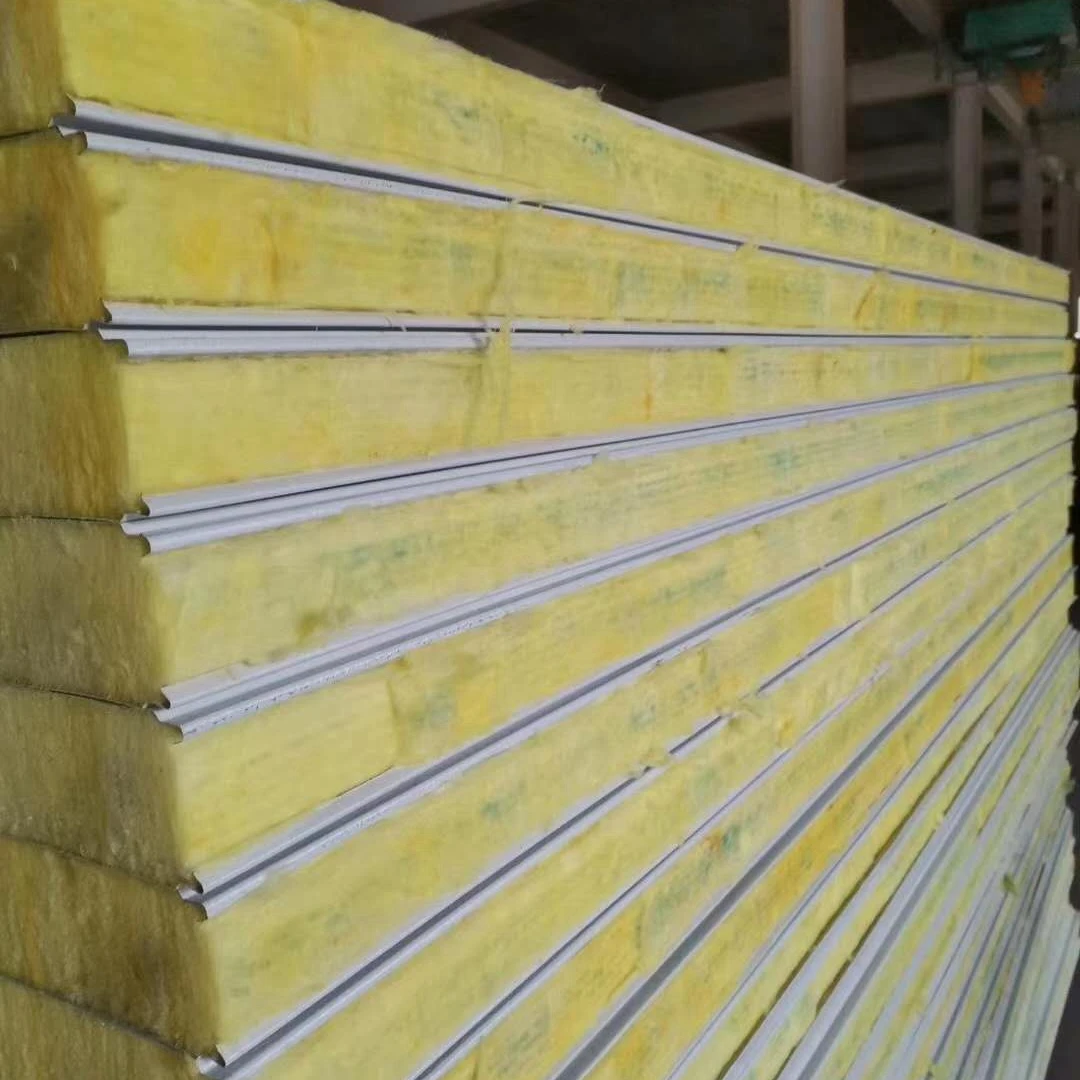

| Wall | color steel insulation sandwich panel | Thickness: 50 / 75mm |

| Door: | steel door | 925 * 1970mm |

| Window | aluminum alloy glass | 925 * 1100mm |

| Ceiling | color steel tile | thickness 0.3/0,45mm |

Highlights of packing cases 1. All the packing boxes are made of Nippon Steel. We have already worked with our suppliers Sign the agreement. At present, 831 ceiling tiles and 831 ceiling tiles are homogeneous parts and composite plates in the box room As well as internal corner parts, folding parts and other accessories, the color of different batches is the same, which is the only one on the market at present A brand building manufacturer, unified overall color manufacturers. All the color papers are made of Lujiang brand, Baosteel products of the same quality. 2. Luxury box, domestic first-line brand, standard size of China Railway Construction Co., Ltd. 3. The daily packing box production can reach 150-200 sets, and now the daily production is in China They are all at the top level. 4. The packing box covers all the models on the market, and it is a kind of packing box on the domestic market Class the most manufacturers, to meet the different needs of customers. 5. Packing box complete set, various types of stairs and walkway awning for different Customer choice, as a brand manufacturer, the service concept is customer first Sincere initiative, professional and efficient. 6. The packing box does not leak the rain, and the production of the box room applied for patent design, the inner wall is higher than On the outer wall, the normal rainwater first flows from the built-in 50 downpipe. When the rainwater is very large, because of the inner wall It is higher than the outer wall, so that the water will flow from all sides and will not flow into the house.